Mixing Circuit Breaker Brands

- Posted By : Iain Williams

- Industry News, Obsolete MCB's

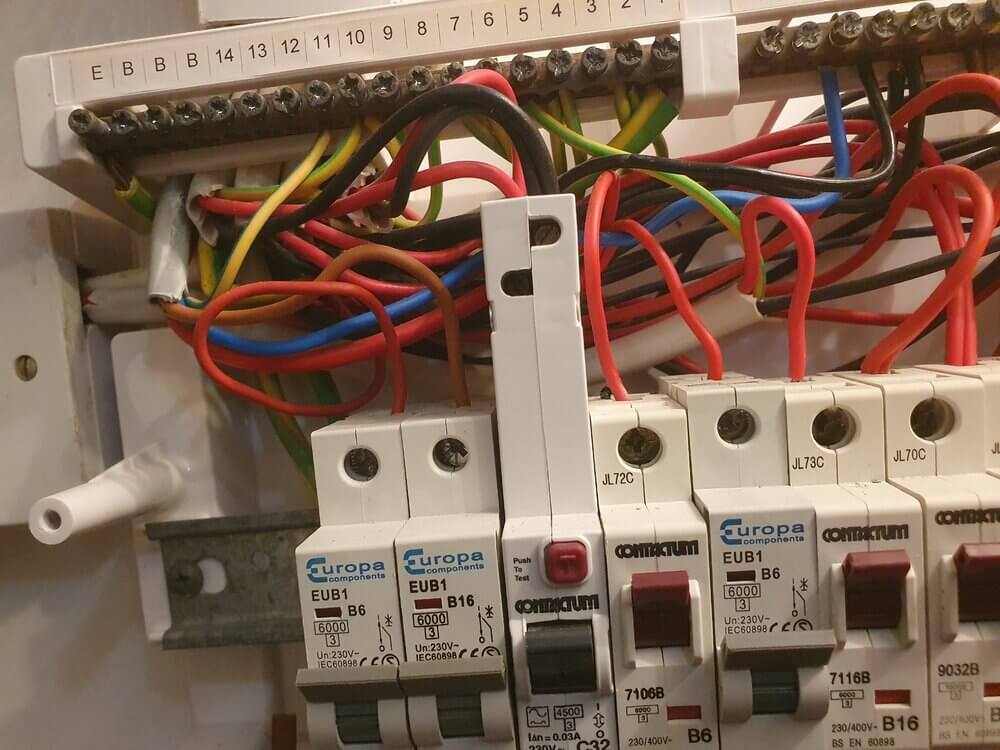

Why You Shouldn’t Mix Brands of MCB's or RCBO's in Consumer Units – According to BSEN61439

In electrical installations, using miniature circuit breakers (MCB's) or residual current circuit breakers with overcurrent protection (RCBO's) from different manufacturers within the same consumer unit might seem harmless—but it’s a serious compliance issue. According to BSEN61439, which governs the assembly of low-voltage switchgear and control gear, mixing brands in this way can compromise safety and invalidate manufacturer warranties.

BSEN61439 requires that a consumer unit (also known as an assembly) is verified as a complete system by the original manufacturer. This includes not only the enclosure but also the protective devices, busbars, and terminals. The standard places the responsibility on the “original manufacturer” to ensure all components work safely and effectively together.

When components like MCB's or RCBO's from third-party brands are introduced, that original system verification is no longer valid. You effectively become the new “manufacturer” of the assembly and are legally responsible for proving its compliance—including testing for dielectric strength, short-circuit capability, temperature rise, and more. For most electricians and installers, carrying out this level of verification isn’t practical—or safe.

Beyond compliance, there are real-world risks. Different brands might have incompatible busbar connections, mechanical interfaces, or thermal tolerances. A mismatched RCBO could fail to trip under fault conditions or cause overheating.

In summary, mixing brands voids the consumer unit’s type-tested status, transfers legal responsibility to the installer, and introduces potential safety hazards. To stay compliant with BSEN61439, always use devices specified by the original consumer unit manufacturer. It’s not just best practice—it’s essential for safety and accountability.

Understanding Different Types of MCB’s

- Posted By : Iain Williams

- Obsolete MCB's

Choosing the Right Protection

Choosing the Right Protection

Miniature Circuit Breakers (MCBs) are essential safety devices in any electrical installation, designed to protect circuits from overcurrents caused by faults or overloads. Selecting the correct type of MCB is crucial for ensuring both safety and the reliable operation of electrical equipment. While you might encounter references to older “Type 1, Type 2, Type 3, and Type 4” MCBs, the current standards primarily categorize MCBs by their tripping characteristics as Type B, Type C, and Type D. Let's delve into both these classifications and also understand the importance of the kA rating under different British Standards.

Understanding the Older MCB Types (Type 1, Type 2, Type 3, Type 4)

These older classifications, often associated with the now largely superseded BS 3871 standard, defined the instantaneous tripping current of the MCB. This refers to the level of fault current that will cause the MCB to trip almost instantly, typically within a fraction of a second.

Type 1 MCBs: These were the most sensitive to fault currents. They typically had an instantaneous tripping current of 4 to 7 times their rated current (In). This meant they would only trip under relatively high fault currents. They were generally used for circuits with minimal inrush currents.

Type 2 MCBs: Offering a medium level of sensitivity, Type 2 MCBs had an instantaneous tripping current of 7 to 10 times their rated current (In). They were a more general-purpose type, suitable for many domestic and light commercial applications.

Type 3 MCBs: These were less sensitive, with an instantaneous tripping current of 10 to 14 times their rated current (In). They were often used for circuits supplying inductive loads that might experience higher inrush currents upon start-up, but still required relatively quick protection against significant faults.

Type 4 MCBs: Being the least sensitive of this older range, Type 4 MCBs had an instantaneous tripping current of 14 to 20 times their rated current (In). They were designed for circuits with even higher inrush currents, such as those supplying motors or transformers.

It's important to note that while you might still find these terms used or encounter these older MCBs in existing installations, the current standard for general-purpose MCBs is BS EN 60898.

The Current Standard: Type B, Type C, and Type D MCBs (BS EN 60898)

The BS EN 60898 standard defines MCBs based on their tripping characteristics in a way that is more aligned with the types of loads they are intended to protect.

Type B MCBs: These are designed to trip at relatively low fault currents. Their instantaneous tripping current is typically 3 to 5 times their rated current (In). This makes them suitable for residential and light commercial applications where the loads are primarily resistive, such as lighting circuits, heating elements, and standard socket outlets. They offer good protection against both overloads and short circuits in these types of circuits.

Example: A 10A Type B MCB will typically trip instantaneously if the current exceeds 30-50A.

Type C MCBs: These have a lower instantaneous tripping current, typically 5 to 10 times their rated current (In). They are designed to handle the higher inrush currents associated with inductive loads such as fluorescent lighting, small motors, and some power supplies. They offer a balance between sensitivity to faults and the ability to withstand temporary overcurrents during start-up. They are commonly used in commercial and industrial installations.

Example: A 10A Type C MCB will typically trip instantaneously if the current exceeds 50-100A.

Type D MCBs: These are the least sensitive to instantaneous overcurrents, with a tripping current typically 10 to 20 times their rated current (In). They are specifically designed for circuits with high inrush currents, such as large motors, transformers, and some types of welding equipment. Their higher tripping threshold prevents nuisance tripping due to these temporary surges while still providing protection against sustained overloads and severe short circuits. They are primarily used in industrial applications.

Example: A 10A Type D MCB will typically trip instantaneously if the current exceeds 100-200A.

The Importance of kA Rating: BS 3871 vs. BS EN 60898

The kA rating of an MCB indicates its breaking capacity, which is the maximum fault current that the MCB can safely interrupt without being damaged or causing a dangerous arc. This is a critical safety parameter.

BS 3871: MCBs manufactured under this older standard typically had lower kA ratings, often ranging from 3kA to 9kA. The specific rating would be marked on the device preceeded by the letter M, so a 9kA rating would read as M9.

BS EN 60898: The current standard, BS EN 60898, generally requires higher breaking capacities. MCBs manufactured to this standard commonly have kA ratings of 6kA, 10kA, or even higher for domestic and commercial applications. Industrial applications may require MCBs with significantly higher kA ratings, often complying with BS EN 60947-2, which can go up to 50kA or more.

Why is the kA rating important?

In the event of a short circuit, a very high fault current can flow through the circuit. If the MCB's breaking capacity is lower than this potential fault current, the MCB may fail to interrupt the current safely. This can lead to:

Damage to the MCB: The MCB could be destroyed, rendering it unable to provide further protection.

Fire hazard: The intense heat generated by the uncontrolled fault current can ignite surrounding materials.

Risk of electric shock: The failure to interrupt the fault current can put individuals at serious risk.

Determining the required kA rating:

The required breaking capacity of MCBs in an installation depends on the prospective fault current at the point where the MCB is installed. This needs to be calculated by a qualified electrician, taking into account factors such as the supply transformer capacity, cable impedances, and the location of the MCB within the electrical system.

In summary:

Older MCB types (Type 1-4) were primarily defined by their instantaneous tripping current under BS 3871.

Current MCBs are classified as Type B, C, and D according to their tripping characteristics under BS EN 60898, relating to the types of loads they protect.

Type B for resistive loads (low inrush).

Type C for inductive loads (medium inrush).

Type D for highly inductive loads (high inrush).

The kA rating indicates the MCB's breaking capacity, which must be higher than the prospective fault current at its location.

BS EN 60898 generally requires higher kA ratings compared to the older BS 3871.

Always consult a qualified electrician to determine the correct type and kA rating of MCBs for your specific electrical installation to ensure safety and proper operation. Using the wrong MCB can have serious consequences.

Obsolete Bill, MEM and Delta Circuit Breakers

- Posted By : Iain Williams

- Obsolete MCB's

- Leave a comment

Delta decided to keep the brands MEM and Bill separate until 1998 when they finally phased out the Bill brand. What most people don't realise is that all the products that were manufactured were identical in both brands. Delta manufactured the products and either labelled them MEM or Bill.

However, just to add a little confusion, some MCB's were discontinued whilst under the MEM brand but due to complaints from customers, specifiers and electrical wholesalers the company had to start manufacturing again. Some of these products are branded Delta and from 2003 some of these products are branded Eaton when they company was bought out yet again.

Confused? Well it gets worse because by the time that Delta/Eaton decided that they needed to manufacturer some of the older products to keep the peace with customers the British Standard BS3871 had changed. Previously all MCB's had been marked with a ‘Type' (either 1,2,3 or 4) but BS3871 had changed so that Type 1 MCB's were no longer used and Types 2,3 & 4 were now Types B,C & D.

So now you have a range of circuit breakers that are either branded MEM,Delta,Bill or Eaton. They may me marked either Type 2,3,4 or Type B,C,D. Some have a printed wrap around label and some have silk screen printing direct on the MCB.

Long and short of it is this. All brands, no matter what Type, colour or creed are interchangeable with each other. So if you are stuck for a Bill MCB, then a MEM, Eaton or Delta will still fit. Likewise if you can't find a particular MEM version then Bill MCB will be a direct replacement.

Moulded Case Circuit Breakers (MCCB's)

Fortunately the situation with Bill and MEM MCCB's is not as confusing. Firstly MCCB's are made to a different standard to MCB's, BS60947-2. Whilst that standard has been updated to allow for new technologies it still remains as the current British Standard.

As with MCB's all MCCB's were manufactured by Delta and either branded MEM or Bill. They are identical apart from the logo and and a slight difference in the part number. You won't find any branded Delta, they never used that branding on any moulded case breakers.

All MCCB's in MEM's Memshield 2 range or Bill's Talisman Plus range are branded as such. Even though Eaton bought out Delta in 2003 they maintained the old branding until they came out with the latest range, Memshield 3. Even though they are using the Memshield brand all breakers are now marked as Eaton.

Still Confused?

If you are still stuck for an obsolete Bill or MEM circuit breaker and this has just confused you even more then please get in touch via our contact page and we will be only too glad to help out.

Choosing the Right Protection

Choosing the Right Protection