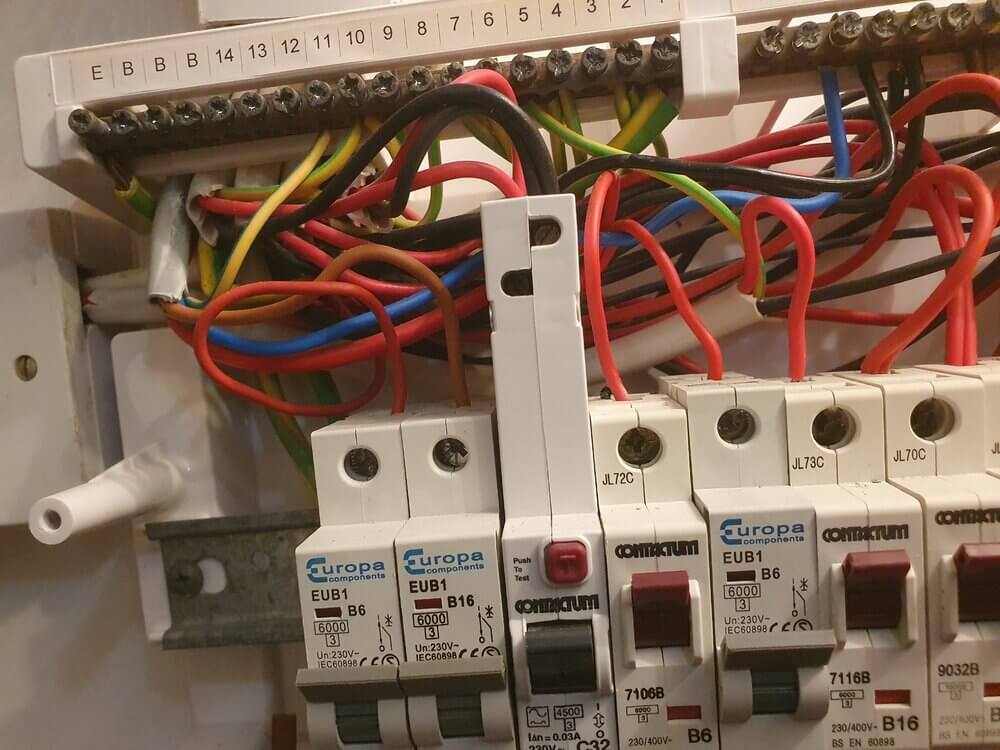

Mixing Circuit Breaker Brands

Why You Shouldn’t Mix Brands of MCB's or RCBO's in Consumer Units – According to BSEN61439

In electrical installations, using miniature circuit breakers (MCB's) or residual current circuit breakers with overcurrent protection (RCBO's) from different manufacturers within the same consumer unit might seem harmless—but it’s a serious compliance issue. According to BSEN61439, which governs the assembly of low-voltage switchgear and control gear, mixing brands in this way can compromise safety and invalidate manufacturer warranties.

BSEN61439 requires that a consumer unit (also known as an assembly) is verified as a complete system by the original manufacturer. This includes not only the enclosure but also the protective devices, busbars, and terminals. The standard places the responsibility on the “original manufacturer” to ensure all components work safely and effectively together.

When components like MCB's or RCBO's from third-party brands are introduced, that original system verification is no longer valid. You effectively become the new “manufacturer” of the assembly and are legally responsible for proving its compliance—including testing for dielectric strength, short-circuit capability, temperature rise, and more. For most electricians and installers, carrying out this level of verification isn’t practical—or safe.

Beyond compliance, there are real-world risks. Different brands might have incompatible busbar connections, mechanical interfaces, or thermal tolerances. A mismatched RCBO could fail to trip under fault conditions or cause overheating.

In summary, mixing brands voids the consumer unit’s type-tested status, transfers legal responsibility to the installer, and introduces potential safety hazards. To stay compliant with BSEN61439, always use devices specified by the original consumer unit manufacturer. It’s not just best practice—it’s essential for safety and accountability.