Mixing Circuit Breaker Brands

- Posted By : Iain Williams

- Industry News, Obsolete MCB's

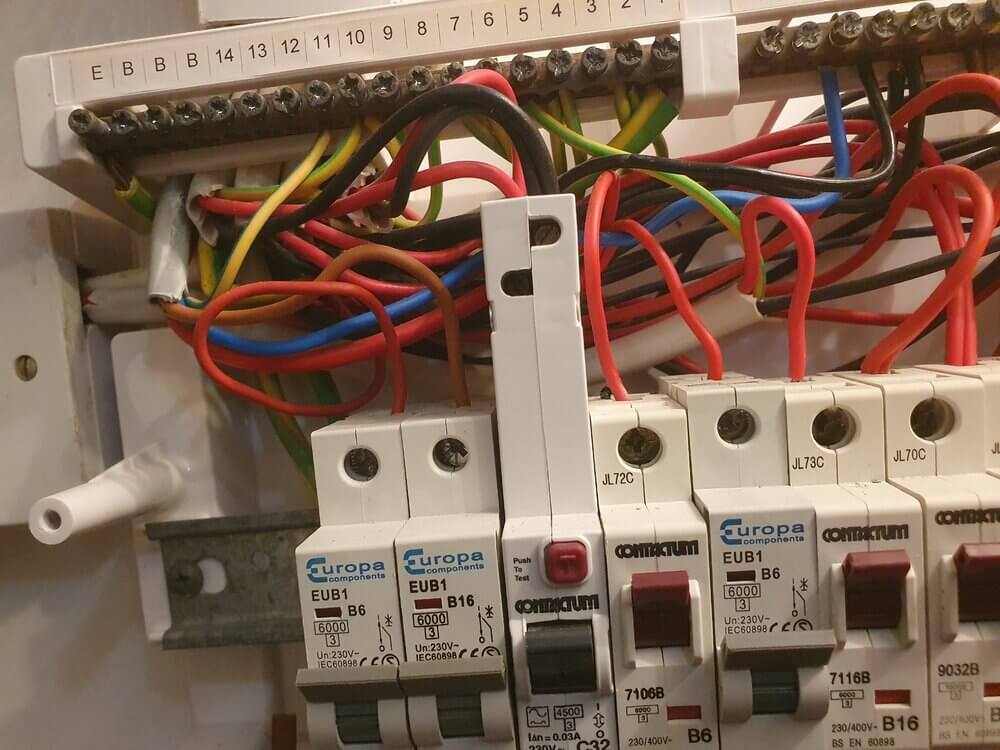

Why You Shouldn’t Mix Brands of MCB's or RCBO's in Consumer Units – According to BSEN61439

In electrical installations, using miniature circuit breakers (MCB's) or residual current circuit breakers with overcurrent protection (RCBO's) from different manufacturers within the same consumer unit might seem harmless—but it’s a serious compliance issue. According to BSEN61439, which governs the assembly of low-voltage switchgear and control gear, mixing brands in this way can compromise safety and invalidate manufacturer warranties.

BSEN61439 requires that a consumer unit (also known as an assembly) is verified as a complete system by the original manufacturer. This includes not only the enclosure but also the protective devices, busbars, and terminals. The standard places the responsibility on the “original manufacturer” to ensure all components work safely and effectively together.

When components like MCB's or RCBO's from third-party brands are introduced, that original system verification is no longer valid. You effectively become the new “manufacturer” of the assembly and are legally responsible for proving its compliance—including testing for dielectric strength, short-circuit capability, temperature rise, and more. For most electricians and installers, carrying out this level of verification isn’t practical—or safe.

Beyond compliance, there are real-world risks. Different brands might have incompatible busbar connections, mechanical interfaces, or thermal tolerances. A mismatched RCBO could fail to trip under fault conditions or cause overheating.

In summary, mixing brands voids the consumer unit’s type-tested status, transfers legal responsibility to the installer, and introduces potential safety hazards. To stay compliant with BSEN61439, always use devices specified by the original consumer unit manufacturer. It’s not just best practice—it’s essential for safety and accountability.

New Consumer Units and BS7671:2008 Amendment 3

- Posted By : Iain Williams

- Industry News

- Leave a comment

Had to bite my tongue a bit as this is not true and looking around some of the electrical forums it seems as though a lot of electricians are under this impression as well.

Amendment 3 came into affect 1st July 2015 but implementation is not until 1st January 2016. Basically this means if you have stock or wholesalers have stock then it can still be used up until this time. It would be prudent though to start using metal as soon as you can but don't go throwing out your old stock, just use it up before 1st January 2016.

Here's the exact wording from the IET web page that specifically deals with the new amendment concerning consumer units:

Implementation date

As stated in Note 2 to the new regulation, the implementation date for the regulation is 1 January 2016. This is six months later than the effective date of Amendment 3 as a whole.

The purpose of the delay in implementation is to allow a period of co-existence of both metal- and plastic-enclosed consumer units and to allow time for manufacturers to work existing and new products through their supply chains. Nevertheless, as is also indicated in Note 2, the delayed implementation does not preclude compliance with the regulation prior to 1 January 2016.

Why Metal or Non-combustible Consumer Units?

This new amendment is supposed to stop the spread of fire if something is not terminated correctly in a consumer unit. Personally I think this is not adressing the root cause of the problem and that is poor workmanship.

I think the rise in fires caused by loose terminations and sloppy work has been a direct result of too many people going on a 6 week course to become ‘Part P' and then claiming they are an electrician. Very few of these ‘6 week wonders' have site experience or the knowledge on exactly how a consumer unit should be terminated.

Whilst the governing bodies allow this to continue we will just see more sloppy work, more fires and potentially more deaths. Changing consumer units to metal is not going to solve the problem. What's next, mandatory metal switches & socket? Self extinguishing junction boxes? Tackle the root problem and get these cowboys off site!